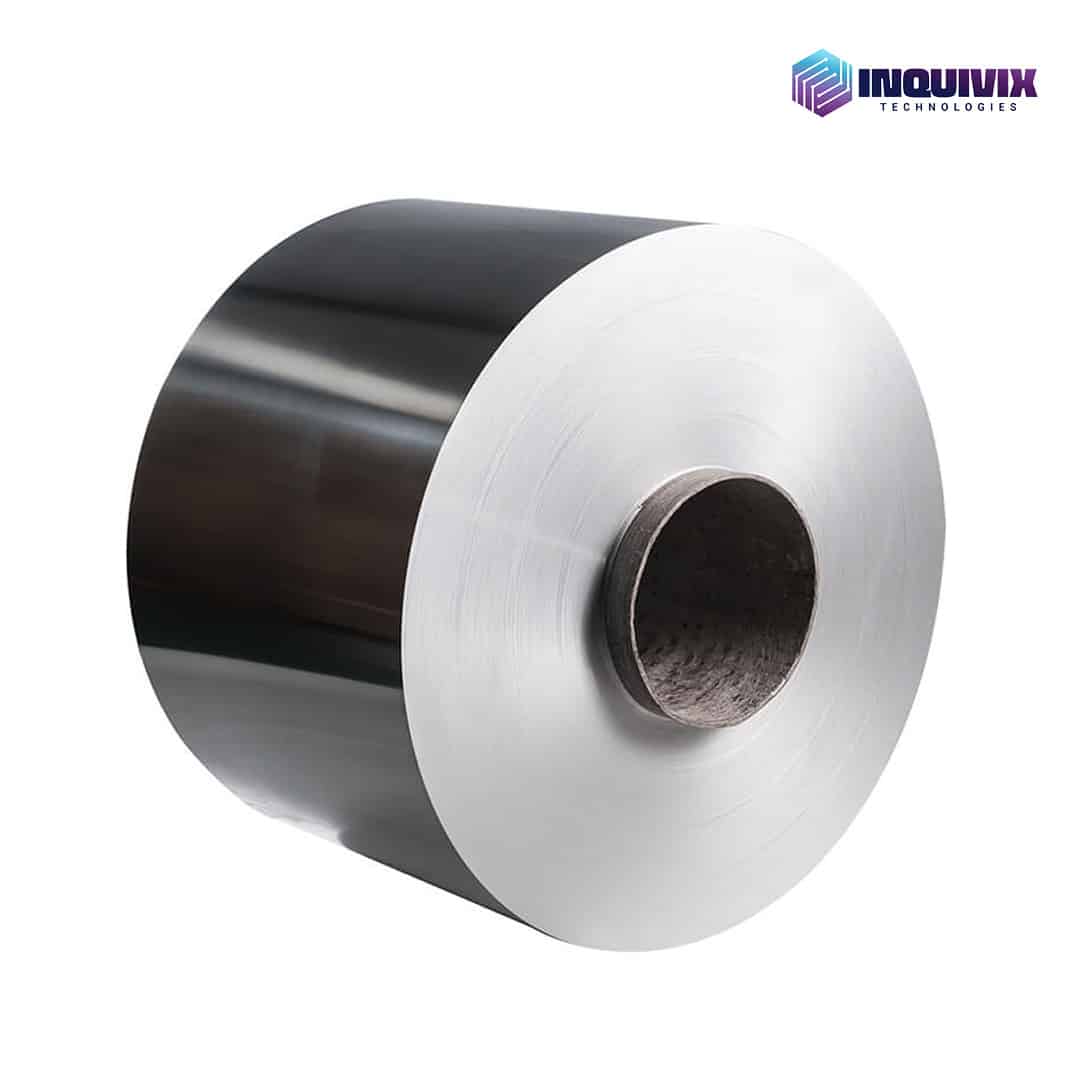

Among the many alloys of aluminum used today, 5052 aluminum is the strongest non-heat treatable alloy that is manufactured and has an impressively high fatigue resistance. This combined with other mechanical properties like weldability, good plasticity, excellent thermal conductivity, and corrosion resistance, make the 5052 aluminum coil invaluable for a wide variety of industrial applications.

The 5052 aluminum coil supplied by Inquivix Technologies is used by our customers in everything from ship construction to manufacturing juice cans. We can deliver cost-effective aluminum sheet, and plate products in addition to the coil, all made to our customer specifications. Let us know the gauge, width, and tempering state you need, and we will ensure your 5052 coils are manufactured to the required tensile strength, yield strength, bendability, and other properties your application demands.

5052 Aluminum Coil Applications

Marine

Applications

Automotive, Aerospace, And Transportation

Architectural, Home, And Office Products

Beverage Cans

Material Properties Of 5052 Aluminum Alloy

Chemical Composition

Of 5052 Aluminum Alloy

| Element | Percentage By Weight |

| Magnesium (Mg) | 2.2% – 2.8% |

| Chromium (Cr) | 0.15% – 0.35% |

| Iron (Fe) | 0 – 0.4% |

| Silicon (Si) | 0 – 0.25% |

| Copper (Cu) | 0 – 0.1% |

| Manganese (Mn) | 0 – 0.1% |

| Zinc (Zn) | 0 – 0.1% |

| Aluminum (Al) | The Remainder |

Technical Specifications of 5052 Aluminum Coil

| Width (mm) | 40 – 2600 |

| Thickness (mm) | 0.014 – 8 |

| Length | As Required |

| Tempered State | F/O/H14/H16/H18/H19/H22/H24/H26/H28 |

Other Aluminum Coil Alloys

Aluminum 8081

Aluminum 3003

Aluminum 1100

Aluminum 1050

FAQs

5052 is an aluminum alloy belonging to the 5xxx series which has magnesium as its primary alloying element along with chromium. 5052 exhibits strength, particularly great resistance against fatigue, corrosion resistance, and weldability, and can be hardened through cold working.

5052 aluminum coil can be used for marine applications like boat construction, automotive components, architectural parts, fuel tanks, kitchen appliances, and carbonated beverage cans.