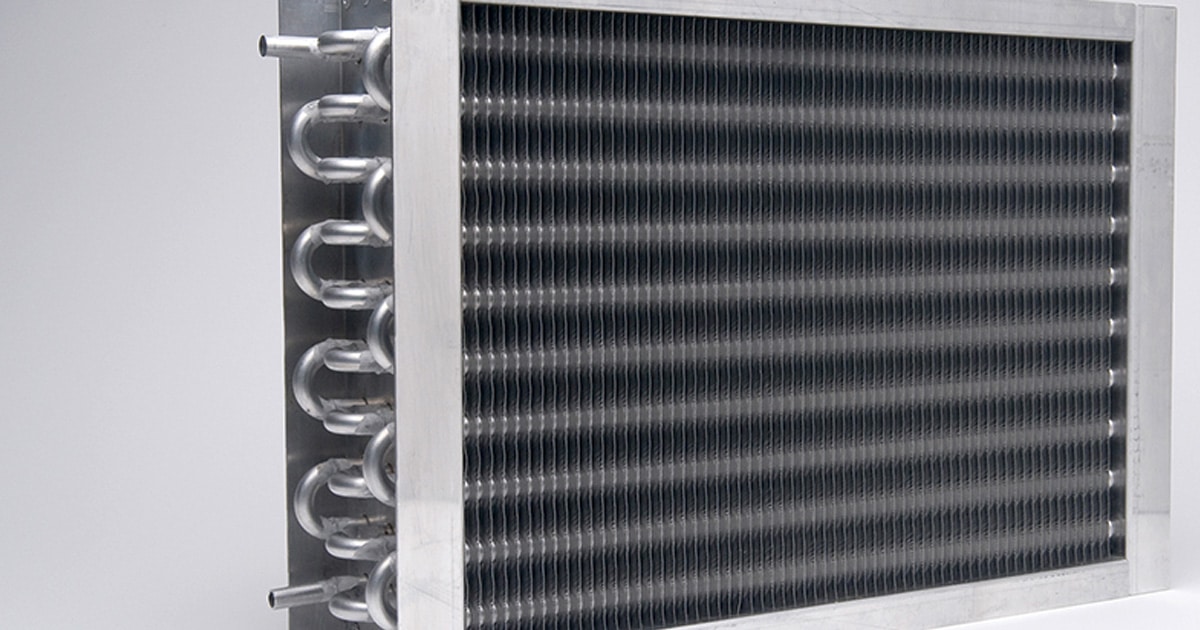

With over 99% aluminum, 1100 is another one of the commercially pure alloy types used widely today. 1100 is not high in tensile strength and is considered soft compared to alloys from other series. This gives it excellent forming characteristics, allowing manufacturers to produce a wide variety of differently shaped products from fin stock used in heat exchangers to cooking utensils.

Our aluminum 1100 coils can be manufactured to customer specifications and delivered anywhere in the world at cost-effective prices. Tempering can also be done to ensure the coils are manufactured to the desired tensile strength or any other mechanical properties the customer desires. Inquivix Technologies is also capable of supplying alloy 1100 in aluminum foil, aluminum wire, and as aluminum sheet products.

1100 Aluminum Coil Applications

Heavy-Duty Structures And Components

Heat Exchanger Fins

Deep-Drawn Stamping Products

Chemical Equipment

Material Properties of 1100 Aluminum Alloy

Chemical Composition Of 1100 Aluminum Alloy

| Element | Percentage By Weight |

| Aluminum (Al) | 99.0 – 99.95% |

| Iron (Fe) | 0 – 0.95% |

| Silicon (Si) | 0 – 0.95% |

| Copper (Cu) | 0.05 – 0.20% |

| Manganese (Mn) | 0 – 0.05% |

| Zinc (Zn) | 0 – 0.1% |

| Other | 0 – 0.15% |

Technical Specifications of 1050 Aluminum Alloy

| Width (mm) | 40 – 1600 |

| Thickness (mm) | 0.014 – 0.4 |

| Length | As Required |

| Tempered State | F/O/H14/H16/H18/H19/H22/H24/H26/H28 |

Other Aluminum Coil Alloys

3003 Aluminum Coil

8081 Aluminum Coil

1050 Aluminum Coil

FAQs

1050 aluminum is an alloy from the pure aluminum series of 1xxx which has an aluminum composition close to 99%. This means it is lower in strength but more resistant to corrosion than other alloy types. It also has high conductivity both electrically, and thermally. 1050 aluminum is very workable and its surface can be prepared easily for decorative or functional requirements.

1050 aluminum coil can be used to manufacture industrial chemical handling equipment, heat sinks, architectural flashing applications, signage, components in electric appliances, cable sheathing, and secondary battery components.