In the heart of environments, precise measurement of tank levels plays a vital role, in ensuring smooth operations maintaining safety, and maximizing productivity. It’s not about determining the content inside storage tanks; it’s a system that monitors temperature, pressure, and volume. This wealth of information is essential for making decisions based on data. Accurate tank gauging goes beyond logistics; it influences process control, inventory management, loss prevention measures, and compliance, with regulations.

As modern industrial operations become complex and demanding traditional methods of tank gauging face challenges. That’s where spring-balanced and servo-balancing type tank gauges come in as the next-generation solutions designed to meet evolving industry needs.

These advanced technology-based tank gauges offer precision and reliability revolutionizing the way we measure tanks. These innovative gauging systems have garnered significant attention as industries strive for efficiency and safety standards. Let’s delve deeper into spring-balanced and servo-balancing tank gauges to explore how they have transformed the landscape as game changers.

Diving into the Basics: Spring-Balanced Tank Gauges

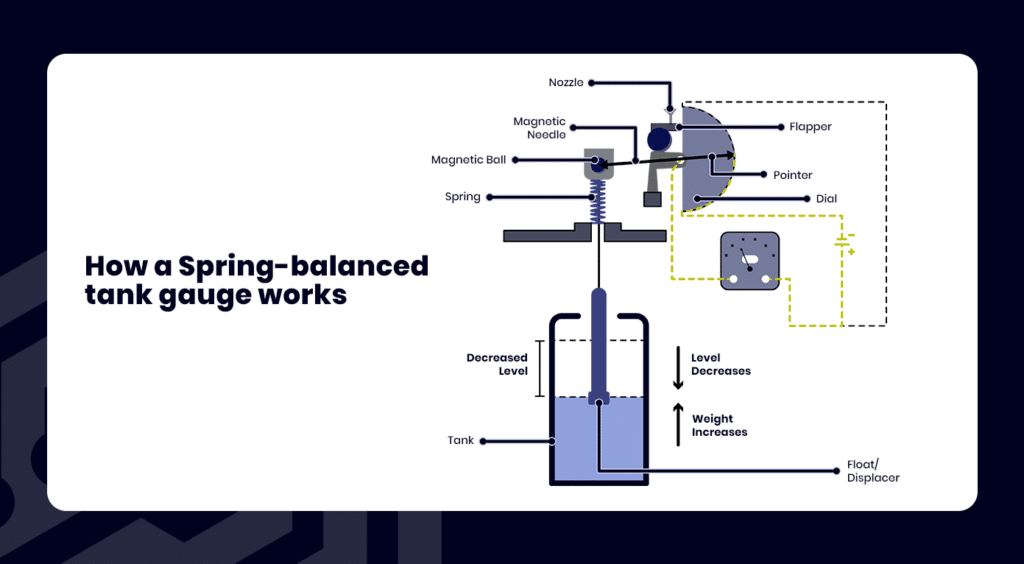

The spring-balanced tank gauge is an advancement, in technology as it combines mechanics with the requirements of modern industries. These systems work on an effective principle. A float connected to a spring counterbalances the pressure exerted by the fluid and any change in the level adjusts the tension of the spring. This change in tension is then translated into a measurement of the tank contents.

What sets apart spring-balanced gauges is their combination of simplicity, durability, and precision. These gauges are designed to withstand conditions ranging from scorching heat to freezing temperatures all while maintaining their accuracy. The result? Industry professionals can rely on readings.

Furthermore, spring-balanced tank gauges require maintenance. Their straightforward design reduces the chances of failures minimizing downtime and associated expenses. This low-maintenance feature makes them a cost-effective solution for businesses of all sizes.

However, the effectiveness of these gauges extends beyond scenarios. They also excel in emergencies providing data to ensure safety. In industries dealing with materials like petroleum and chemicals, these reliable gauges play a role, in preventing unwanted incidents.

However, it’s important to note that the spring-balanced tank gauges are not the measurement tools transforming industrial operations. There is another contender, in the market that takes things a step further—the servo balancing type tank gauge.

A Step Further: Servo-Balancing Tank Gauges

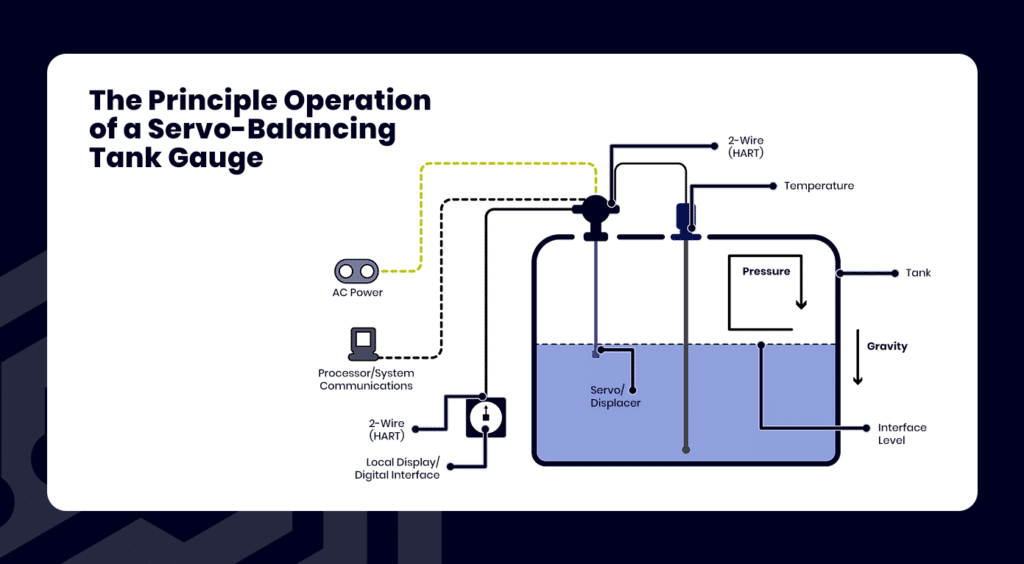

The tank gauges of the servo balancing type represent an advancement, in the field offering a combination of accuracy and versatility to meet various industrial needs.

These systems operate based on the principle of servo operation. In terms, a small displacer attached to a measuring wire is submerged in the tank. Precisely positioned to measure the level of liquid, interface level, and specific gravity. A sophisticated processor interprets this data. Transforms it into insights about the contents of the tank.

The precision of servo-balancing gauges is unparalleled making them highly suitable for applications where precise measurements are crucial. Whether it’s a change in temperature, pressure, or content level these gauges. Provide real-time updates empowering businesses to make prompt and well-informed decisions.

However, functionality is one side of the story. Servo balancing gauges are also designed with user experience in mind. Their digital interfaces are user-friendly and easy to navigate simplifying tasks for employees and reducing training time. This user-centric design elevates them from being tools to becoming partners, in efficient operations.

Moreover, servo balancing tank gauges boast a construction that ensures lasting performance. They are designed to function in challenging industrial environments providing businesses with a guarantee of continuous and dependable service.

The introduction of spring servo balancing tank gauges has undoubtedly changed industrial measurement systems. However, the question remains; how do these two systems compare? Let’s explore an analysis of these tank gauging systems.

Comparing Spring-Balanced and Servo-Balancing Tank Gauges

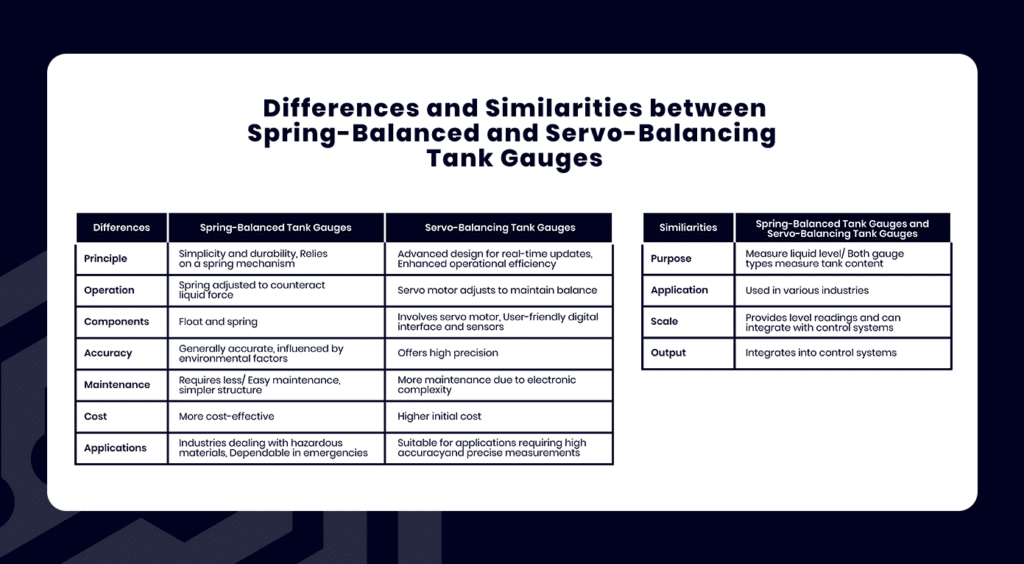

Spring-balanced and servo-balancing gauges serve the purpose. Have distinct characteristics that make them suitable, for different situations.

Spring-balanced tank gauges excel in their simplicity and durability. Their mechanical nature ensures reliability in environments. The straightforward design reduces the chances of failures making them easy to maintain. These gauges provide readings during emergencies making them a dependable choice for industries dealing with hazardous materials.

On the other hand, servo balancing tank gauges stand out in terms of accuracy and versatility. Their advanced design allows for measurements and real-time updates on the slightest changes in tank content, temperature, or pressure. This exceptional accuracy makes them ideal, for applications that require measurements. Additionally, their user-friendly digital interface simplifies operations and improves efficiency.

When choosing between these two options it ultimately depends on the needs of your industry. If you require a maintenance and reliable solution that can withstand tough conditions spring balanced gauges would be an excellent choice.

On the other hand, if you require measurements, instant updates and a user-friendly interface, for your operations servo balancing gauges could be the perfect option.

However, it’s important to note that the decision-making process doesn’t stop here. There are aspects to take into account when selecting the appropriate tank gauges. Let’s delve into these factors in the following section.

Navigating Your Purchase: A Comprehensive Guide to Choosing the Right Tank Gauges

When selecting the tank gauge it’s not, about choosing between spring-balanced and servo-balancing systems. It involves an evaluation of factors including the specific requirements of your industry and operations. Let’s dive into the considerations in detail:

Considering the Liquid Type

The type of liquid stored in your tanks has an impact on how gauge systems interact with it. For example, if you’re dealing with substances you’ll need gauges that have sealing properties to prevent any dangerous leaks.

Accounting for Environmental Conditions

Your operational environment plays a role well. If your tanks are located in areas with weather or extreme temperatures the gauge you choose must be resilient enough to withstand these conditions.

Assessing Accuracy Requirements

The level of accuracy you require from your measurements is another factor to consider. Different industries may tolerate measurement errors. Others demand absolute precision. Your gauge system should align with these accuracy needs.

Evaluating Tank Specifications

The size and configuration of your tanks can also influence which types of gauges are suitable for them. Always make sure that the gauge you choose is fully compatible, with the dimensions and shape of your tank.

Weighing Maintenance and Costs

Lastly, it’s important to take into account the expenses associated with owning and operating a system. This includes both the investment and the ongoing costs of maintenance. While certain systems may have expenses they could result in significant long-term maintenance costs or vice versa. Striking a balance, between these two factors will help you make a cost decision.

With this guide at your disposal, you’ll be able to make an advantageous choice for implementing tank gauging methods, in your business. Stay tuned for a summary of points. Discover how these advanced tank gauging techniques can contribute to your business success.

Leveraging Advanced Tank Gauging for Business Success

In today’s changing landscape the pursuit of efficiency, safety, and achieving optimal output drives every business decision. In this context incorporating cutting-edge tank gauging techniques such, as spring servo balancing systems is not an improvement but a strategic step towards achieving success, in the industry.

When chosen wisely, these gauges offer several benefits:

- Enhanced Accuracy – With precise measurements, you can better control your processes, optimize usage, and eliminate unnecessary waste.

- Improved Safety – Accurate gauges help avoid overfilling and other hazardous situations, contributing to a safer working environment.

- Increased Operational Efficiency – Real-time updates about tank content aid informed decision-making, resulting in improved process efficiency and productivity.

- Compliance with Regulations – With advanced gauges, ensuring compliance with legal and environmental regulations becomes easier, protecting your business from potential legal complications.

After conducting a comparison, between spring servo balancing gauges, it becomes apparent that each type has its own strengths and ideal applications. Spring-balanced gauges are highly durable and reliable making them suitable for certain conditions. On the other hand, servo balancing gauges excel in precision and user-friendliness making them perfect for situations that require measurements.

However when making the decision it is important to consider your industrial requirements. This includes factors such as the types of liquids stored, environmental conditions, desired accuracy levels, tank specifications, and overall costs.

Integrating this technology into your operations can establish a foundation, for success. Embrace the power of tank gauging techniques today. Take your business to new heights.

FAQs

Environmental conditions greatly influence the selection of tank gauges. For instance, in areas prone to harsh weather or extreme temperatures, durability is a key consideration. You’ll need a gauge robust enough to maintain accurate readings under these conditions. Spring-balanced gauges, renowned for their robustness and reliability, could be an excellent choice for such environments.

Looking at the total cost of ownership rather than just the initial investment is crucial when selecting tank gauges. Some systems may seem cheaper upfront but could incur hefty maintenance costs over their lifetime, impacting your operational expenses. Conversely, a system with higher upfront costs but low maintenance requirements could be more cost-effective long term. Balancing these factors leads to a more considered financial decision.