Integrated circuits or microprocessors are present in nearly every type of modern consumer electronic device. There are sophisticated systems that perform all manner of tests to ensure that the microchips in your smartphone or tablet are in good working order before they are shipped out of the factory. As a result, semiconductor test equipment is increasingly playing a vital role in the production process and is in high demand.

Keep reading to find out more about semiconductor chip testing, why it’s important, and how it is performed using automated test equipment.

Why An IC Test Is Important

In semiconductor manufacturing, no process can provide a 100% yield. Some of the integrated circuits or microchips produced from semiconductors can contain faulty areas arising from several factors like contamination, surface defects, and so on. These issues can make the semiconductor device unusable or cause it to fail. Since semiconductor devices are used in nearly every modern piece of technology from the latest automobiles to airplanes and medical equipment, they mustn’t fail during normal use.

Therefore these chips need to be screened by the manufacturer to identify faulty products before they are made available for the customer to purchase. This screening process is called semiconductor testing or IC testing and semiconductor companies take this very seriously. There is also semiconductor failure analysis which is done to determine how a semiconductor device failed, although this is done after it has been used by the consumer and not during the production stage.

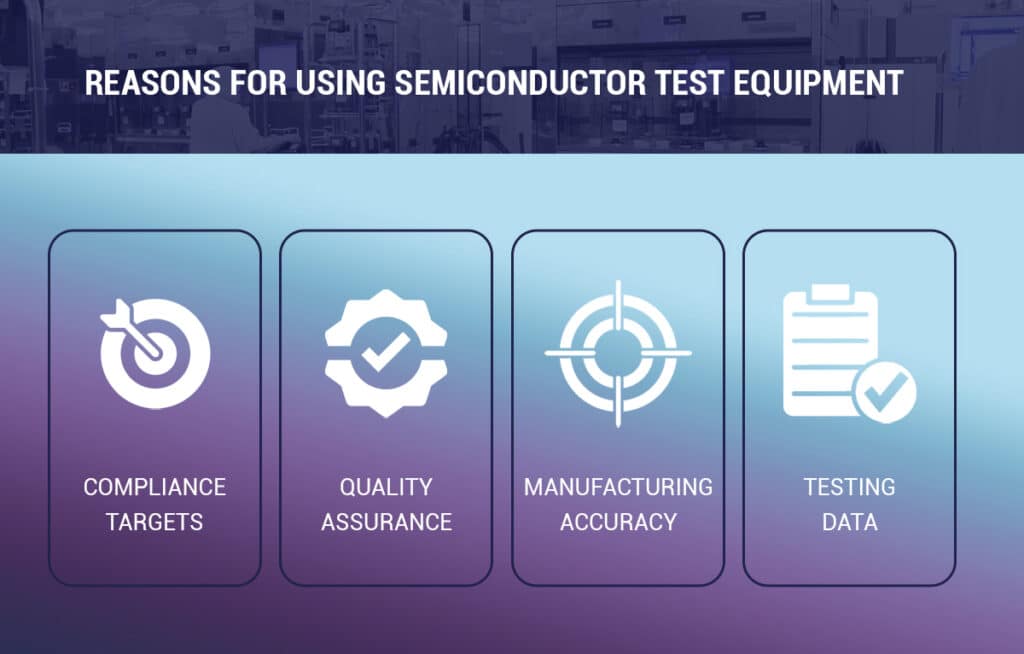

Reasons For Using Semiconductor Test Equipment

Semiconductor test equipment or automated test equipment is used by semiconductor manufacturers to screen for faulty products. Also known as an integrated circuit (IC) tester, this test equipment provides electrical signals to a semiconductor device and observes the output signal produced by it. These output signals are then compared against the expected values indicated in their specifications. Any major deviations in the test results from the specified values will reveal a faulty product.

Apart from being a final test to ensure the consumer doesn’t end up purchasing a faulty product, there are other reasons for using semiconductor test equipment.

Compliance Targets

There are compliance targets that need to be met for every semiconductor device that is produced. If the testing data is outside the expected range, that product cannot be shipped to the market. The International Electrotechnical Commission (IEC) is the organization that sets

fabrication standards for semiconductors that the entire industry is expected to follow.

These standards apply to everything from semiconductor cleanrooms that maintains the optimum manufacturing environment within a fabrication plant, how a semiconductor test must be conducted, electromagnetic requirements, fabrication methods, and various other industry-specific standards for aviation.

Quality Assurance

Customers expect nothing less than electronic devices that work as advertised. Companies in the semiconductor industry take great measures to make sure that every device they sell meets all quality standards without any unknown issues that can cause it to fail. IC testing is what puts high-quality products in the customer’s hands while rooting out the faulty ones.

Manufacturing Accuracy

Defective products can be the result of the manufacturing process. By conducting semiconductor testing during the fabrication process of wafers and afterward, it is possible to identify at which stage the defect was introduced into the product. Any equipment or process issues can then be rectified to ensure no further deviation can compromise the integrity of the products made on that production line.

Testing Data

The complexity of semiconductor devices is always increasing while their size continues to shrink. Semiconductor wafers made from new materials, innovative fabrication methods, new equipment, and process improvements are made all the time as well. IC testing provides important data that allows manufacturers to understand what works and what doesn’t.

Automated Test Equipment (ATEs)

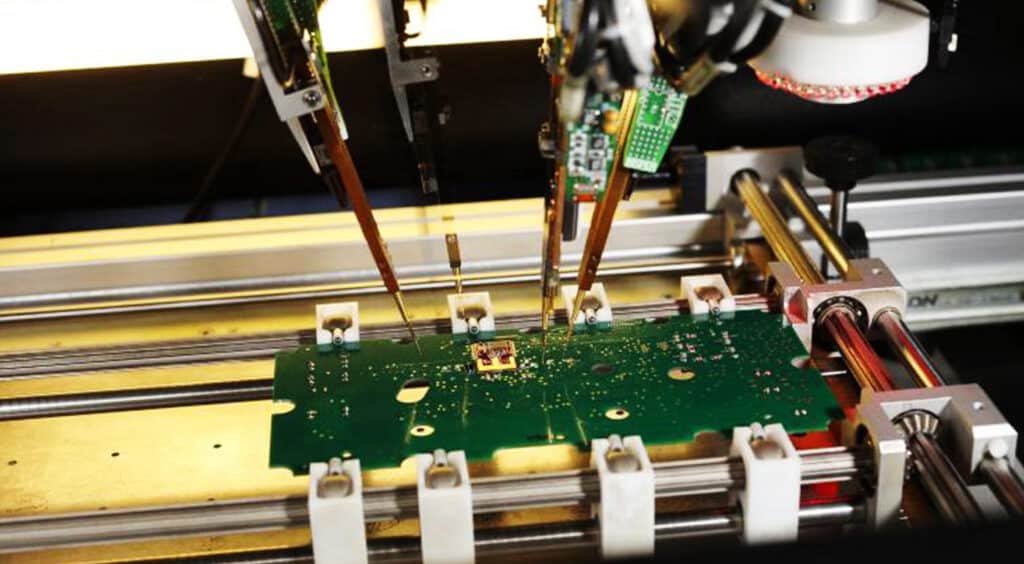

Semiconductor test equipment also known as automated test equipment, are powerful IC testing diagnostic tools used to ensure that all semiconductor products that make it to the market function as advertised and do not pose any danger to the customer through a malfunction. This sort of IC testing used to be performed by human technicians but many of their operations have been automated, hence the name.

A typical IC tester or ATE system in the production environment is made up of precise control systems called ‘handlers’ to manipulate the device being tested (DUT), and test probes to make contact with the device. Through a computer workstation, a technician can run various software testing programs which introduce the specific stimuli of electrical signals to the DUT. The resulting output signals are then recorded, evaluated, and presented on screen.

The automation of semiconductor test equipment has allowed the testing of devices to be done at high volume, an absolute necessity when you consider the insatiable demand for chips around the world. Automated test equipment has reduced testing time and costs, allowing repeatable testing to be conducted at a massive scale.

Normally, an IC tester is used to perform a package test also called a final test that is performed after packaging. Through a wafer probe, unpackaged chips on the surface of wafers can be tested as well. By doing this, faulty components can be removed early, reducing the cost of packaging them. There are many types of semiconductor test equipment available such as logic testers, printed circuit board testers, and memory testers.

Logic Testers

Logic testing is done according to the components that are being evaluated. Passive semiconductor devices like resistors and capacitors are tested by applying a simple current. Active components like transistors and diodes are tested using discrete ATEs. There are also much more complex electronics like digital-to-analog converters (DACs) or analog-to-digital converters (ADCs). These types of devices, that have both analog and digital components including signal processing modules, transceivers, or audio interfaces, are tested using mixed signal ATEs.

Printed Circuit Board (PCB) Testers

PCB testers come in a variety of models. First, there are the manufacturing defect analyzers (MDAs). These are analog testers used with the DUT cold or powered down. As the name suggests, they can detect manufacturing defects such as missing components and shorts. Analog testers are much more affordable than other more complex testing equipment.

There are also in-circuit analyzers, also known as digital circuit testers where the DUT is placed in a circuit and powered up (hot). Finally, there are functional tests that can be performed by ATEs that simulate the operating environment for a DUT. It is then tested and compared with its specifications to identify any deviations.

Memory Testers

Last but certainly not least are the memory testers which are the ATEs that have some of the highest demand at the moment. Components like RAM modules and Flash drives are being used in all sorts of consumer electronics, and ensuring their functionality is the objective of memory testers.

The Semiconductor Test Equipment Market

Asian Pacific countries like Taiwan, South Korea, Japan, and China supply the major share of semiconductor test equipment. Although ATEs are not cheap, the demand for test equipment that can handle large volumes of DUTs with minimal human interaction is increasing. This growth is due to the boom in smart consumer electronics which drives the semiconductor industry to produce more ICs, and as a result, the automated test equipment market to perform quality control of those chips.

The global ATE market was worth US$ 5.91 billion in 2020 and shows no signs of slowing down as it is expected to reach US$ 9.02 billion by 2031. To find out more about semiconductor test equipment, semiconductor products, or the latest industry news, check Inquivix Technologies.

FAQs

Automated test equipment (ATE) or an IC tester is a system that applies electrical signals to a semiconductor device and records its output. These readings are then analyzed to determine if the device is functioning as intended according to its specifications.

The handler is the sophisticated mechanism of an IC tester or ATE that precisely moves the chip into place to and from the testing terminal. It may also be capable of automatically sorting functional or faulty chips based on the test results.